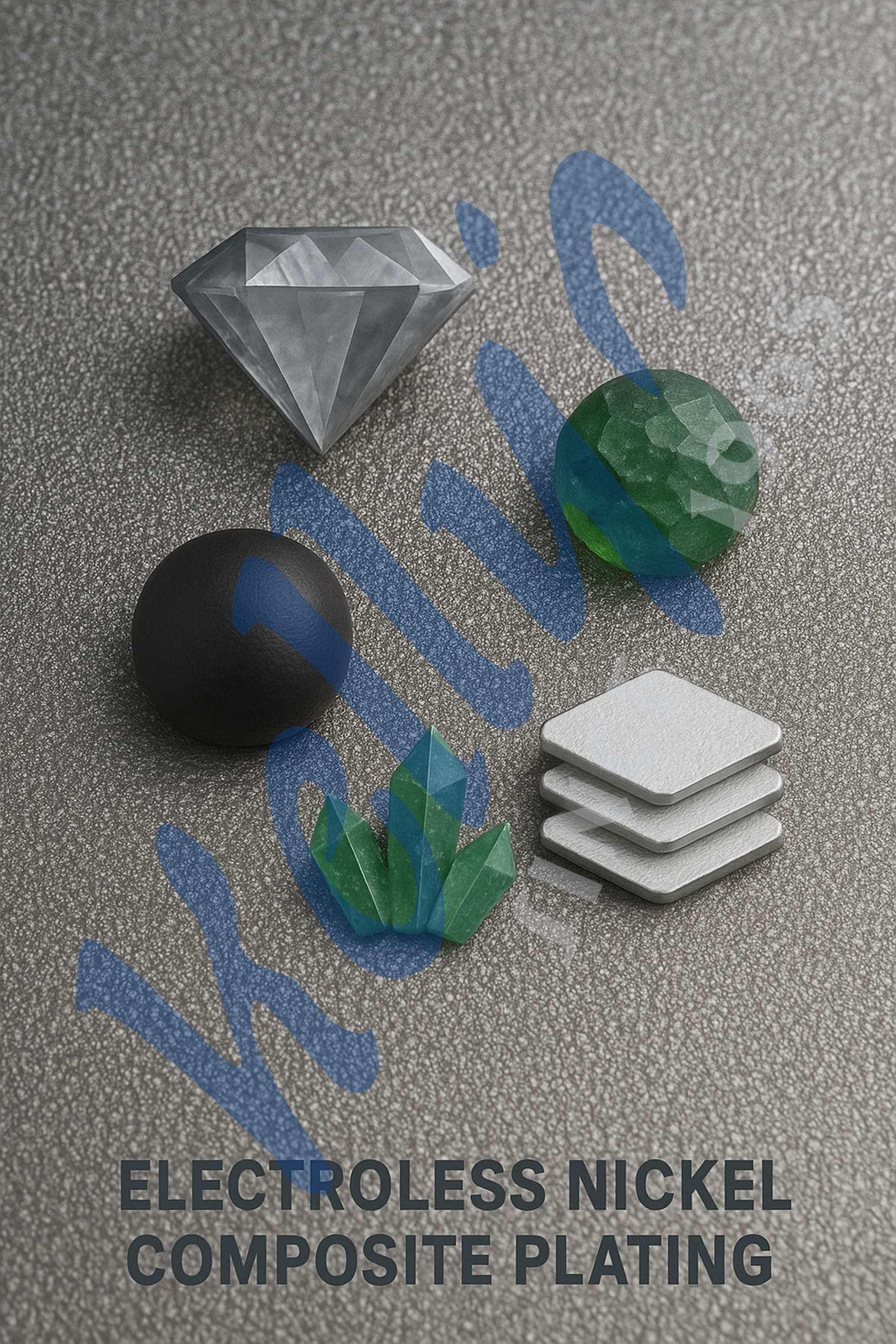

Electroless Nickel Composite Plating: Key Features of Diamond, PTFE, SiC, and BN

Jun 23, 2025

Introduction to Electroless Nickel Composite Plating

Electroless nickel plating is an autocatalytic chemical deposition process that forms a uniform and hard nickel-phosphorus or nickel-boron alloy coating on metal surfaces. When functional or hard particles (such as PTFE, SiC, etc.) are introduced into the plating bath, a composite coating is formed, greatly enhancing properties like hardness, wear resistance, lubrication, and corrosion protection.

Feature Comparison of Common Materials

| Material | Key Characteristics | Typical Applications |

|---|---|---|

| Diamond | - Extremely high hardness (second only to natural diamond) - Exceptional wear resistance - Ultra-hard surface finish | High-end cutting tools, precision wear parts, mold surfaces |

| PTFE | - Excellent self-lubrication - Very low friction coefficient - Non-stick properties | Lubricated components, anti-stick molds, sliding bearings |

| Silicon Carbide (SiC) | - High hardness and wear resistance - Good thermal stability - More cost-effective | Tool parts, automotive components, corrosion- and wear-resistant coatings |

| Boron Nitride (BN) | - Layered structure similar to graphite - Excellent high-temperature stability - High lubricity and electrical insulation | High-temperature bearings, electrical insulation, dry lubricants |

Application-Based Recommendations

-

For maximum hardness and extreme wear resistance ➜ Use Diamond or Silicon Carbide.

-

For lubrication or low friction needs ➜ Choose PTFE or BN.

-

For high-temperature or chemically stable applications ➜ Consider BN.

-

For cost-performance balance ➜ SiC is a strong candidate.